AirStrings Technology provides manufacturers and consumers with an innovative cushioning material that has enhanced capacity for:

AirString is a flexible,washable,breathable,recyclable material

Starting with well respected Linear Low Density Polyethylene (LLDPE) polymers, AirString has developed a unique cushioning material which capitalizes on LLDPE’s proven tubular and hygienic properties. These highly successful polymers have been used in a variety of non-cushioning fields, and, LLDPE’s have been the material of choice for food grade containers.

When our AirString team was searching for a solution to overcome the problems with present cushioning materials, they realized LLDPE’s offered a unique opportunity for a vastly improved user experience. After intensive development and testing, the AirString product does just that. It lasts much longer than present applications and provides significantly increased comfort levels.

The secret to this futuristic material is how it is formed from raw polymer into a breathable, pressure reducing cushion.

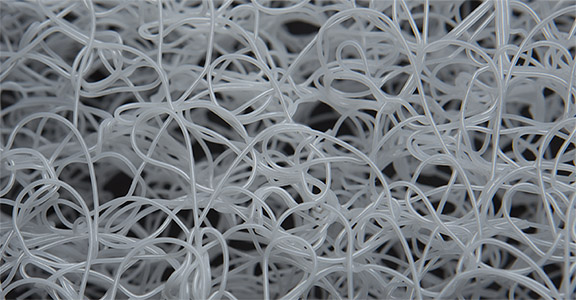

The highest quality hygienic polymer possible is extruded into a pool of water, creating a unique, resilient three-dimensional shape that is 90% air by volume. This provides excellent breathability for products where ever microclimate control is important. For example, testing shows that, when integrated into a mattress core, the material encourages airflow and regulates body temperature throughout the night, aiding in restorative sleep.

AirString is an LLDPE polymer formed into a nest-like structure of interconnected strings surrounded by pockets of air.

RESIDENTIAL USE

Today’s mattress consumers are also concerned about the need for evenly distributed support for their bodies as they sleep. Foam cores, which offered so much promise, have been disappointing, developing, over time, permanent indentations which distort the support patterns.

AirString technology, on the other hand, maintains equal support across the mattress because it gathers into a nest-like structure that provides great shock absorbing and surface pressure reduction benefits. Energy from impact is absorbed and dispersed evenly throughout the AirString material. Because the strings are all interconnected, when one string buckles from impact, other strings extend to help absorb the force. This results in a long term capacity to rebound and regain the original shape .

INDUSTRIAL AND INSTITUTIONAL USE

This rebound quality makes our technology the ideal material for high impact applications like safety barriers. Since it also results in a significantly longer product life, it is the preferred cushioning for heavy and repetitive use applications such as hospital beds, airline seats and bench pads in public areas.

Since many applications for AirString involve prolonged contact with people or pets, hygiene is a critical component. Our innovative technology offers a three-fold advantage for healthier use:

The white color in the material is from added fire retardant

Some applications require specific additional properties. We offer flame retardants, biocides, and color pigments to meet stringent performance requirements and specifications for your particular application. Click on the INDUSTRIES link to learn how this exciting technology can give you and your clients a new long term cost-saving cushioning solution.

AirString starts off as beads of LLDPE ploymer